what jb weld to use to bond metal to aluminum

The list of items that JB weld doesn't work on is a lot shorter than the items it does. Once perusing that list, y'all will find that this product is merely short of beingness a miracle worker. It handles a long listing of issues when you can't afford to rent a welder.

Does JB Weld piece of work on aluminum? Yeah, JD Weld volition do a great job bounden aluminum pieces together. In fact, in that location are very few materials information technology does not work on and you can count those almost on one hand.

Brand sure to follow the instructions to get the best bond possible as it volition hold for years when applied correct.

To learn more well-nigh JB weld and how well it works, but go on to read our commodity. Information technology has the information you want to know about. This epoxy at present adheres to lead which will be a bonus to those who have problems with lead connections.

Will J-B Weld Work On Aluminum?

This epoxy comes from a very reputable company that has been in business organization for merely over 50 years. The visitor makes very potent adhesives, so strong that it does work on aluminum.

But not everything is as golden as one would like. While this epoxy works on small repairs, bigger jobs volition need an experienced welder to set. Some of those bigger repairs would be structural and would be too complicated and difficult for JB Weld. From all reports, JB Weld epoxy works like a charm on those smaller issues.

Some people have reported no issues from months to years after applying this adhesive to their different problems. By post-obit the instructions, they have become very satisfied customers as they do non accept to proceed running to the shop to get other products to do the job.

How Strong is J-B Weld On Aluminum

According to some scientific tests, the tensile strength of JB Weld reaches 5020 psi roughly. To reach that level of strength, y'all have to let the epoxy to cure overnight. The set-upward time is 4-six hours and the curing time is between xv and 24 hours.

Once you let information technology set and cure, you lot should not have whatever problems with your repair. One boat possessor said it fixed problems on his aluminum gunkhole and he has not had a leak problem in vii months.

That is probably because he did not use the fabric on any weight-bearing objects. That volition be the issue with this product. No matter how stiff it is, at that place will be some situations it is not suited for. Non because it is the wrong metal but because information technology is not designed to hold a lot of weight.

So make sure you apply this epoxy to the correct broken issue to avoid having to repair the part more than than once.

Liquid Aluminum Weld

Before using any product that falls under this category, y'all have to do good surface prep if y'all desire the epoxy to attach and class a tight bond. If yous don't do skilful surface prep work, you may get frustrated.

Even with JB Weld, y'all have to chaff the end with a prissy flat file and then use a wire brush to score the stop. That scoring should reach up to an inch wide from the end you are adhering.

Only it will depend on the type of joint y'all are trying to create. Sometimes, equally good as JB Weld is the product won't hold the joint overnight and go brittle. That is because this product has a filler in information technology that does become brittle overnight.

This may be ane of the weaknesses that JB Weld products accept. There are amend and stronger adhesives out there that will agree any articulation when it is fabricated from aluminum.

Best J-B Weld for Aluminum

Most likely, the best JB Weld product for aluminum would be their Marine Weld choice. It is designed for boats that must handle very tough weather condition that most RV users do not face.

Y'all mix the ii tubes at a 1 to 1 ratio and after application, you let information technology sit down for 4 to 6 hours and and then cure for up to 24. Simply once information technology has gone through that procedure, y'all can sand, tap, fill up, mold, and drill the cloth to make sure y'all have the perfect concur.

This product is also steel reinforced and tin handle temperatures reaching 550 degrees F. One time it is totally cured, it is waterproof and resistant to petroleum, chemicals, and acid. Being below water doesn't weaken this epoxy.

You lot may notice comparable JB Weld products as the visitor works difficult to make sure its products are the best quality and does the job they claim it does.

JB Weld Aluminum Cure Time

One matter the company does that makes information technology easier to buy their products, is that they put the setup and cure times front and center. That allows y'all to see right abroad what time frame you demand to work with this agglutinative.

Generally, the setup time is 4 to six hours while the cure time is between 15 and 24 hours. If you are not in a bustle it is all-time to wait till the cure fourth dimension is over before testing the repair.

Yous volition find that at that place are other products on the market that do not take equally long to cure or set but their tensile strength may not be as nifty as JB Weld'south 5020 psi. Their packaging too gives you the color their epoxy volition dry likewise after the curing time.

In one little box on the packaging, you become a lot of information about the production. That data helps y'all decide if yous want to use it or not.

JB Weld for a Pigsty in Aluminum

Ane of the best applications for this epoxy is fixing holes. If you take a stripped commodities or hole, turning to JB Weld products is a smart move to make. Threads practice not always concord upwards under a lot of stress, utilize, or other tension-producing uses.

They strip out adequately easily and when they practise JB Weld tin can come to the rescue. Yous can fill the pigsty with this product and allow information technology set up and cure. Once that is done, you can tap the epoxy to the depth you need and put the bolt back in.

Or if you want a permanent set, utilise the epoxy to the bolt itself and put information technology back into its original spot. Once the epoxy dries, that bolt is never going to motility again. Other holes are no problem for this production equally long as they practice non get too big.

With bigger holes, y'all may need other solutions or weld some other slice of aluminum over the pigsty with JB Weld products.

Tin can You J-B Weld Aluminum ac Lines?

While some people report a fiddling bit of success on certain AC parts, the full general consensus is that this is the wrong cloth to fix an Ac line. The JB Weld epoxy cannot handle the high pressure required for Ac lines to part right.

If y'all take a break in the line, about everyone recommended that yous get a new line and solve your problem the correct fashion. JB Weld is seen as the cheap way of making an Air-conditioning repair and it is not going to do the job you want.

The phrase 'you lot get what you pay for' applies to this state of affairs and it would be best to repair any Air-conditioning line correctly so it will last for a long time. This epoxy doesn't concluding for very long when used to correct broken issues.

Talk to a professional and they will tell you the same thing. If y'all want the repair to last, practise information technology the right mode the first time. In this case, JB Weld is not the right way.

JB Weld Aluminum Radiator?

Like the AC situation, there are success stories and then there are those pieces of advice that say the product doesn't work very well in this situation. Since JB Weld epoxies are non that expensive, you lot can try it and see how practiced a hold you become.

But we volition non guarantee any results as there are too many contrary pieces of data that say information technology is non a long-term solution. If you are out boondocking and you lot spot a leak in your radiator, JB Weld would be a practiced stop-gap fix till you got to a repair shop.

The problem with using this epoxy even for a stop-gap measure out is that it is hard to clean off once it cures. Most people recommended welding the radiator to make sure yous got the right gear up to the problem.

There are hot and cold temperature limits to this product so yous should be careful where you employ it.

Does J-B Weld Work On Aluminum Engine Block?

I of the keys to welding this crack together is that you accept to spend a good amount of time making certain the crack is gratuitous from pigment, rust, and liquids. Later on cleaning the crack with a wire brush, you should wipe it down with rubbing booze.

Let the booze dry before applying the JB Weld epoxy. Next, utilize a ane to 1 ratio of hardener and resin and mix the two until they are the same color. So, take a scraper and put the epoxy into the crack. Yous may demand to press hard to get the mixture to the back of the crevice and actually seal it.

When you lot are washed, await till the next day to run across how the epoxy is ready and cured. And so starting time the motor and let information technology get up to the normal operating temperature and check to meet if the epoxy held or not.

Because people are getting dissimilar results, we will not guarantee that your crack will be fixed and you lot tin bulldoze for years that way. Test information technology out to make sure you got a adept hold. Of course, the size of the crack will play a role in your success or not.

Will J-B Weld Piece of work On Aluminum Boat?

This material has been applied successfully to aluminum boats. If you read the section about the best JB Weld product, yous would have seen how good this product is for aluminum boats.

The central to your success will be if the repair is weight-bearing or not, or too large for the epoxy to handle. While the Marine weld is peak quality, it does have its limits and yous should be realistic in your application of this agglutinative.

Keep in mind that JB Weld products are not conductors and then if you want to join two aluminum wires in your boat, this product won't work for you lot. It is good for smaller repairs and one time information technology cures it does become waterproof and then it can piece of work on those issues that are beneath the surface of the water.

Read the package to brand sure the epoxy volition work on your type of repair. There should be limits placed on them then you know where to apply the adhesive and where to avert using it.

Can You lot J-B Weld Aluminum Oil Pan?

As long as the crack is non also large, width-wise, you should have success in using this product on your cracked oil pan. The biggest consequence in using this production for that repair is the time it takes to fully cure and be set for use.

Once information technology is cured, JB Weld is supposed to be resistant to petroleum products. That ways you should be able to use your car without worry. The key will be waiting for the up to 24 hour time flow. When you repair make sure you do non need your vehicle before so.

Brand sure the oil pan crack is overnice and make clean and also free from any oil earlier you employ this agglutinative. Clean off the oil thoroughly before doing any repair work. The product may be resistant to oil, but it doesn't attach that well, if at all, if oil is present in the cracked expanse.

JB Weld Aluminum Wheel Frame

The issue of using this production on bike frames is fairly cut and dried. The aluminum bike frame is basically weight-begetting. That means that this production is not that good at repairing the crevice. Information technology doesn't piece of work that well on weight-begetting items.

Even regular welding is discouraged because aluminum does non render to total strength after welding. In this case, aluminum is not like steel. Where steel returns to total force, if not stronger, later welding, aluminum remains weaker and you could have problems with the frame if you ride it.

Nigh people say to become a new frame then that you are not putting yourself or family unit members at hazard. Fifty-fifty if you try to weld the parts together in the traditional manner, yous would even so demand to anneal it then take information technology re-tempered in order for the frame to be safe to ride once more.

Volition J-B Weld Bond Aluminum to Steel?

JB weld is said it can be practical to whatsoever metal. Information technology does not say that the two pieces of metal have to be made from the same materials. This adhesive is supposed to be great at adhering aluminum to steel. It is too great at adhering other metals to steel.

When you have a small non-load begetting weld to make, then this is the production you demand to use. It has a very stiff agglutinative formula that makes certain your metallic pieces stay together. Also, it will bond aluminum to other metals also.

There are very few materials where JB Weld does not course a stiff bond, making it an ideal product to use when you have smaller repairs. Every product has its limits so you should check the packaging to make sure what the limits are in this situation.

JB Weld Aluminum to Plastic

Plastic is i of the materials this weld does Not work with. It is not just that there is a weak bond, it is that the product is not designed to adhere to this material. information technology is keen when you want to weld 2 pieces of metal together but not plastics or metallic to plastic.

Regular plastic is non the only material JB Weld does not work with. Polypropylene and polyethylene plastics are also not able to bond with this epoxy. Other materials include vinyl, leather, and canvas.

If y'all want to fix a tarp, and then you have to use an agglutinative designed to work with tarp materials. Check the package before you lot purchase it to spare yourself any embarrassment when you lot have to render it and purchase something that is suited for the plastic materials you want to weld together.

JB Weld Aluminum to Forest

The give-and-take is that this epoxy volition work on forest. The visitor kept it off the list of materials their products do not work with then you lot can use this adhesive when you lot need to weld metal to wood.

That is the fundamental. You get a great bond when welding metal to forest but not and then great when trying to weld wood to wood. At that place are amend wood-to-wood adhesives than JB Weld. Those are the ones you should utilise when that is your situation.

From what we have been able to find out, you tin weld whatsoever metal to wood using this production. There seem to be no exclusions and so y'all have lots of freedom when working on your repair or project.

All the warnings about the size of repair and weight-begetting will apply hither as well.

How to Use JB Weld On Aluminum

The first stride is to brand sure the aluminum pieces are clean. This ways scraping off any dirt, rust, and other contaminants. Then once those items are off, you need to use a solvent to make clean off any grease or oil that remains.

You lot may need to score the aluminum where you are going to apply the epoxy. A good wire brush should handle this chore. A 1 to 1 ratio of the ii liquids is needed and use something disposable to do the mixing on.

Then follow the instructions on the package. You will have to work speedily as once you experience whatever heat coming from the mixture the chemicals are reacting and brainstorm to ready sooner than yous think.

After applying the epoxy, clamp the two items together so that the adhesive tin can class a strong bail. Wait the required curing fourth dimension before you begin to apply the particular. Usually, that will be one day after you have clamped the items together.

How to Sand J-B Weld

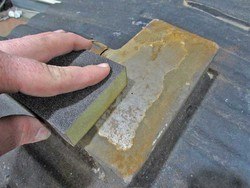

Sanding is done as you would usually sand metal. Almost people are talking about the pre-sanding you lot have to exercise earlier you use the glue. At that point, you demand to use coarse grit sandpaper to rough the metal pieces up.

After the material has cured, you sand like normal just use a finer grit slice of sandpaper to brand sure the surface is smooth and not jagged. If you want to fully remove JB Weld and so you are in for a lot of work as it has to be taken off with a grinder or filing it. Extreme heat volition do the job as well, over 600 degrees F.

Some Final Words

JB Weld is a keen welding tool when yous practice non ain a welder or you only need a small repair done. It bonds to the metal and holds the pieces together very tightly, even aluminum.

Its weaknesses include load-bearing repairs and cracks that are too big.

Source: https://thecampingadvisor.com/does-jb-weld-work-on-aluminum/

0 Response to "what jb weld to use to bond metal to aluminum"

Post a Comment